Start small, think BIG

Do It Yourself (DIY), How To... and a lot of Photography tips.

By Rui M. Leal

Showing posts with label Do It Yourself. Show all posts

Showing posts with label Do It Yourself. Show all posts

DIY: Umbrella Softbox Reinforcement

Hello 2015!! Hope you all have a wonderful year with lot's of assignments and great stuff to photograph.

It's been quite a while that I did not post anything here on the blog, time flies and so do things. The world spins so quickly these days that you almost do not have time to spare on something else than shooting and family. For me traveling been an easy and wild ride that most of the time I don't have a moment to spare with the blog and unfortunately started to be left behind

Well, enough of this and the post I bring you today is an easy one and I been planning on writing on this for quite sometime, that the time has come ;)

More and more I've been traveling for assignments and getting myself with the same dilemma: Travel=Lightweight.

This means less things to bring onto a shoot and travel lighter either by having a small camera and lenses or having to choose lighter lighting gear and all portable. So I decided to give it a go to my Umbrella Softboxes I had in the closet, first because they are easy to travel with and also very quick to assemble on location, you just pop them open like an umbrella and there you have it a self contained softbox.

My last acquisition was the Phottix 90x90cm with grid, man this thing is BIG (not bulky), very portable and not very expensive. Excellent for on location shooting and travel! Not a BIG MAMMA but BIG and good for portraits and small group shots.

The thing is, I had already noticed that the interior of this type of boxes were not well attached together and can sometimes cause it to have disruption at the metal parts, either by letting her fall on the floor by wind blowing, by mistake or simply by opening it up and closing it to many times.

The 4 tissue attachments that came in are not suffice to make this thing steady (I also noticed the same thing on some other different sizes Umbrella Softboxes from this same brand).

Well they hold it together great but if you make some heavy duty work with it then this DIY solution maybe something that you would like to consider done to yours.

It's simply adding some inexpensive Nylon Cable Ties to join the 2 metal pieces together. This way you will have a stronger softbox, just by doing this DIY (Do It Yourself) on all metal bars that hold the softbox together.

Let's see how:

First what will you need to make this DIY happen:

- Wire Cutter

- 24x White Nylon Cable Ties (200mm) 0,50€ a pack of 50

You can choose whatever color you want on the Cable Ties, I preferred the white ones so it can be neutral, since the background of the box is silver and because visually it pops less to your eyes ;)

Here is one of the 4 tissues that attach the metal bars together on each side of the softbox.

Here you have one of the Nylon Cable Ties firmly securing the metal bars together next to the tissue one.

Grab the 2 bars together, here you have to take some attention for not letting the bars cross before you zip in the Nylon Cable Tie, otherwise you will end up with a distorted bar..

Zip in the Nylon Cable Tie and move on to the next. I zipped in 6 Nylon Cable Ties on each metal bar.

Here is the distance I've done of each Nylon Cable Tie near the top center shaft.

I did not push the zip too much on the closest to the center so it will not bend the metal bars. Tight it a little but not too much.

Here is another image of the distance between the first two Nylon Cable Ties.

Cut the long edge of the Nylon Cable Tie and you are ready to go.

Here is the final image of my box.

The Red circles are the Nylon Cable Ties I had and the Green ones are the tissued ones that came already in the box.

I used 6 Nylon Cable Ties on each of the 4 metal parts of the box. I think 6 will suffice but you are able to attach more if you want to.

By making this simple DIY you are making the 4 metal parts more rigid and durable since now they are secured to each other instead of floating around.

Hope this would help you on getting a more steady Umbrella Softbox so it could last a little longer.

Until next post... stay safe and THANK YOU for the support!!!

DIY: Spring your batteries on Olympus OMD-EM5 Battery Grip Holder HLD-6

---//--- UPDATE 2014-06-24 ---//---

Received a call today from Olympus European Service Center that is located in Coimbra, Portugal and they have informed me, that after reading my DIY, that in fact there may be some kind of random grips out there that may miss the spring but they assure me that the Olympus Battery Grip Holder HLD-6 have in deed the spring at the bottom.

They asked me to return my Battery Grip Holder HLD-6 so they could apply the missing spring at no charge.

Once again KUDOS for Olympus on fast solving this issue and their excellent Service Center Support, just wish Canon was like this when I had several problems with cameras and lenses while on Platinum CPS.

If your Olympus Battery Grip Holder HLD-6 is missing the spring call it in so they can add it... meanwhile use the DIY as a rescue option.

---//---

It's been quite a while since I posted anything here on the blog... the lack of time has made me left out writing and DIY postings on the blog as well as some bumps here and there.

Anyway, today's post it's about something that have been annoying me for quite some time on my Olympus OMD-EM5 battery holder the HLD-6.

I do not know if this also happens to you or is a random case, I've never have report it to Olympus, that's a fact, but that's is very annoying it is.

Let me explain this... When I got the grip my batteries came out quite easily. I have some from Olympus and some from a "white" brand since they are much less expensive and can take the same charge as the branded ones also the chargers have a travel plug that easier to put in the bag than to have to carry the cable around.

After some travels and bumps the grip got some kind of a malfunctioning problem while sometimes it will work and others simply won't responded even after removing the batteries and putting them back on. So I send it to service and while still on guarantee Olympus service center (that is in Coimbra, Portugal) was kind enough to replace the bad parts and the service was so good that I recommend it greatly to anyone using their services. UPS will pick up and will deliver with a great service.

Things started to be a bit more difficult to remove the battery just when I got it back from the service center. It looks like the bottom metal plate is nor a little curved or not well positioned and the batteries are less easily removed.

I now have to use a small knife to remove them because of how tight they are and has you can imagine this is a little bit difficult to do when on assignment.

So I decided to have a small paper clip with me and use it to remove the batteries, but sometimes even with the paper clip to help this can take sometime and when you and to be fast to remove the grip battery it can take forever and when in a dim light situation you can sometimes go crazy.

In order to fix this I decided to look why was this happening since when I bought the OMD-EM5 I never remembered this has ever happened and the battery after pressing the release button it will pop out so easily.

Here is the answer... the OMD-EM5 have a small spring inside near the battery connectors that makes the battery pop out when you press the orange release button.

Hey!! no spring on the battery grip HLD-6, very strange has it seems to have some kind of attachment inside where a spring should fit easily. Could it be mine or Olympus simply forgot to put the spring inside the HLD-6? Fear Not Not I will teach you how easy is to make a replacement one for your HLD-6.

Here are some things you will need:

- Scissors

- Some gaff tape

- Broken radio or a small spring

- Long tweezers

- Small spanner (to make a small hoke on the gaff tape)

So let's start.

Remove the spring form the radio or other accessory you have at hand

where you can get a small spring. In my case was this broken radio.

Here is the spring out of the radio.

Here is the size in cm so you can have an idea of how small it is.

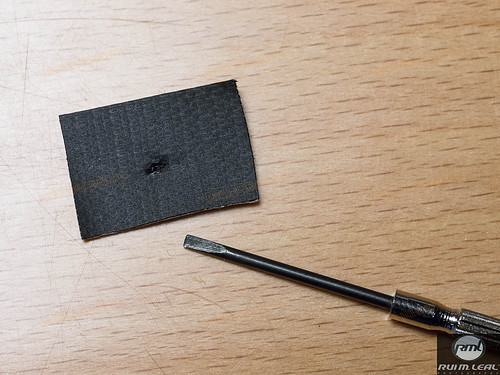

Now cut a small square of a gaff tape, more or less like so. This you have to take in attention has the room inside the battery holder HLD-6 has not a lot of parts where you can glue this to... so take that in attention but this was the size I cut mine.

With a small spanner I made a very small hole so that the spring can roll inside of it. Do not make a very big hole or the spring will not hold.

With the help of the tweezers I put the spring inside the hole and twist it a little bit so it won't come out so easily.

There you have it.

This is how much I have roll it in the back of the gaff tape.

Then with the help of the long tweezers I carefully glued it inside the bottom of the battery holder HLD-6. Use the tweezers to press the gaff tape to the bottom of the grip holder.

Now when you press the orange release button...

The battery will pop out has it does on the OMD-EM5.

Some things you have to take in consideration when making this DIY.

The spring eventually will be loosen has the gaff tape will not hold the rest of the battery grip holder life. This is because the glue with the heat may come out and the spring will get loosen but until it does I'm pretty sure it will take a couple of months.

When popping the battery out always double check to see if the spring is still there and in the correct position before you put another battery in, this will help you on not having problems when that gaff tape start to loose it's magic ;)

Hope you enjoy this and I will tag Olympus on this post maybe they will have a permanent replacement, in the future, for this DIY fix.

I'm pretty confident that this will be very easy to fix at factory level since there is some kind of attachment already inside the grip but for unknown reason they are not using it and I do not see how a small spring could affect the price increase of the future grips.

Let's hope Olympus will service this and give us a small spring for our grips.

Thank you for following and hope you have enjoyed and if you make one just let me know how it went.

Stay safe,

Rui

DIY: Sensor Brush Visible Dust Motor Replacement

In a previous 2008 post I taught you how to clean your sensor (Cleaning Dust Bunnies With a Butterfly), I know that back then we were in 2008 and cameras were not so evolved in auto cleaning sensor technology now in 2013 a lot has changed but since then the only real factor that changed was an upgraded the Arctic Butterfly new version the 724 (Super Bright) which now is equipped with 2 super bright LEDs Sensor Brush and changed it's color to a marine blue ;)

This Arctic Butterfly been traveling with me all over the place, from dusty environments to some splashy ones and well... a couple of weeks ago the brush motor just got it's last days and at a certain point it stopped rotating completely.

So I decided to make my hands dirty and find a replacement for it.

It's been a while that I did not post anything here on the blog on DIY (Do It Yourself) matter so here goes this post, to the fans of DIY, that I hope it would help you save a couple of bucks on buying a new one.

I will take you step by step on how to simply replace the motor with a much better and quite one ;)

Enjoy

Well first it took me a couple of days to really find a replacement unit for the motor itself. Just because I did not have any clue or idea what kind of motor or what type and RPM the guys at Visible Dust were using for theirs.

Luckily I found, here in Europe, RobotShop.com and these guys have almost any kind of motors for... well just take a look at their page and you will see what I'm talking about.

Well first let's start with the gear we need to make this simply replacement.

This is an easy procedure and what we need is:

- Damaged Arctic Butterfly ;)

- New motor Brushed DC Motor (RM1A) RB-Sbo-48

- Small knife to open the plastic case (nothing special here) and actually do not even need to cut.

- Welding Iron

- Some soldering

First let's start with the new motor that I happily found at RobotShop and that you can safely order has they ship very quickly to any place in Europe

Here is the direct reference for the motor

Brushed DC Motor (RM1A) RB-Sbo-48

It's not the same motor as the original Arctic Butterfly but it fits perfectly.

Here you can see the back part of the new motor RM1A with the connections.

Here is the label order :)

Then I just attached the brush to see if it fit's the hole and it works, Excellent !!!

Next Step, you just open the battery cover of the Arctic Butterfly, remove the batteries and put the brush inside the protective cover so it won't get contaminated with oil or dust.

REMEMBER that the bush tips cannot touch anything or else it will contaminate your sensor with dust or oil particles. This is a tool that needs to always be clean, just remember that.

Now lets carefully open the Arctic Butterfly by starting near the button switch. This would be a much easier place to start open it up as soon has you lift it it will pop open. Not too much pressure needed.

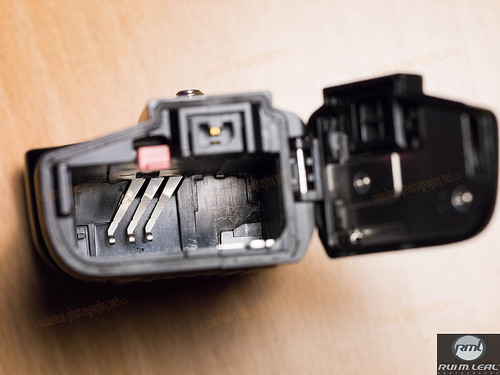

Here it is... this is what looks inside.

Now let's remove the button switch and put it aside so you don't loose it.

This is the switch button and you can see the hole where it connects to the switch inside the cover and this is, when you assemble it later on, the part that goes down inside the hole.

Next you carefully lift the motor. You can see here that my motor had already a couple of visible damage and time corrosion and also some kind of oil inside??? (go figure...)

Closer look at the motor.

At this point you can clearly see that it has 2 soldering connection one by the red cable and the other on the yellow cables that goes also connects to the 2 front led's. Also notice that at the yellow junction is an iron part connected that comes from the battery connector and also needs to be soldered with the yellow cables.

Let's Start by unsoldering the red cable has this would be much easier to start from.

Now to the other side we unsolder the yellow connection cables.

Here is the connected silver iron that I talked earlier and that also needs to be soldered with the yellow cables so the motor can have it's power.

(This iron piece can be easily removed and later on put it to place with no problem).

Let's take a look at a side-by-side on the motors. On the right you have the new one and at left the older model.

You can see now that they are different and also the connections are on a different position but the new one fits almost perfectly in the cover.

This is what looks like when you remove the old motor. You see that the box it's full of some kind of oil that later on I've cleaned before putting the new motor. Maybe this happens because the motor is opened... well who knows...

To make it easier to solder I just put some solder on the tips before I started the procedure this way it will ensure me a quick solder of the parts. I've solder the + side to the red wire.

You can see that I've also removed the battery connect iron part so I can solder it better with the yellow connections.

Here in detail after putting the iron part to place. I also had to bend it a little bit has the connections were a little apart from the old motor one's.

Side by Side of the motors.

Another side by side view of the motors.

Let close this thing up by first putting the button switch into place.

Put some batteries and pray...

Insert the brush...

Ups... I noticed that something wasn't right has I tested the motor before closing and everything was working good but when I put the brush it did not worked :(

Fear not... quick and closer look revealed that at some point when closing the shaft the mother been pressed to one side and now the brush is touching one of the parts of the case.

Let's open this again and check out what is going on...

GOT IT!!!

Since the motor has a closer connections to the body part it touches this plastic mount at far back.

I just use an x-act to cut the tips of the plastic so that the motor connections would not touch it.

I did not unsolder the motor I simply and carefully moved it aside so I can cut this.

And after this last step I have my working and trusty Visible Dust Artic Butterfly working again.

What I noticed from the older model is that this one is a much more quite one and does not zuuummmbbb that much.

Hope this could help you save a couple of bucks when yours stop working.

If you want to know how to use it please also read my 2008 article Cleaning Dust Bunnies with a Butterfly

Subscribe to:

Posts (Atom)